Quality

Our Commitment to Excellence

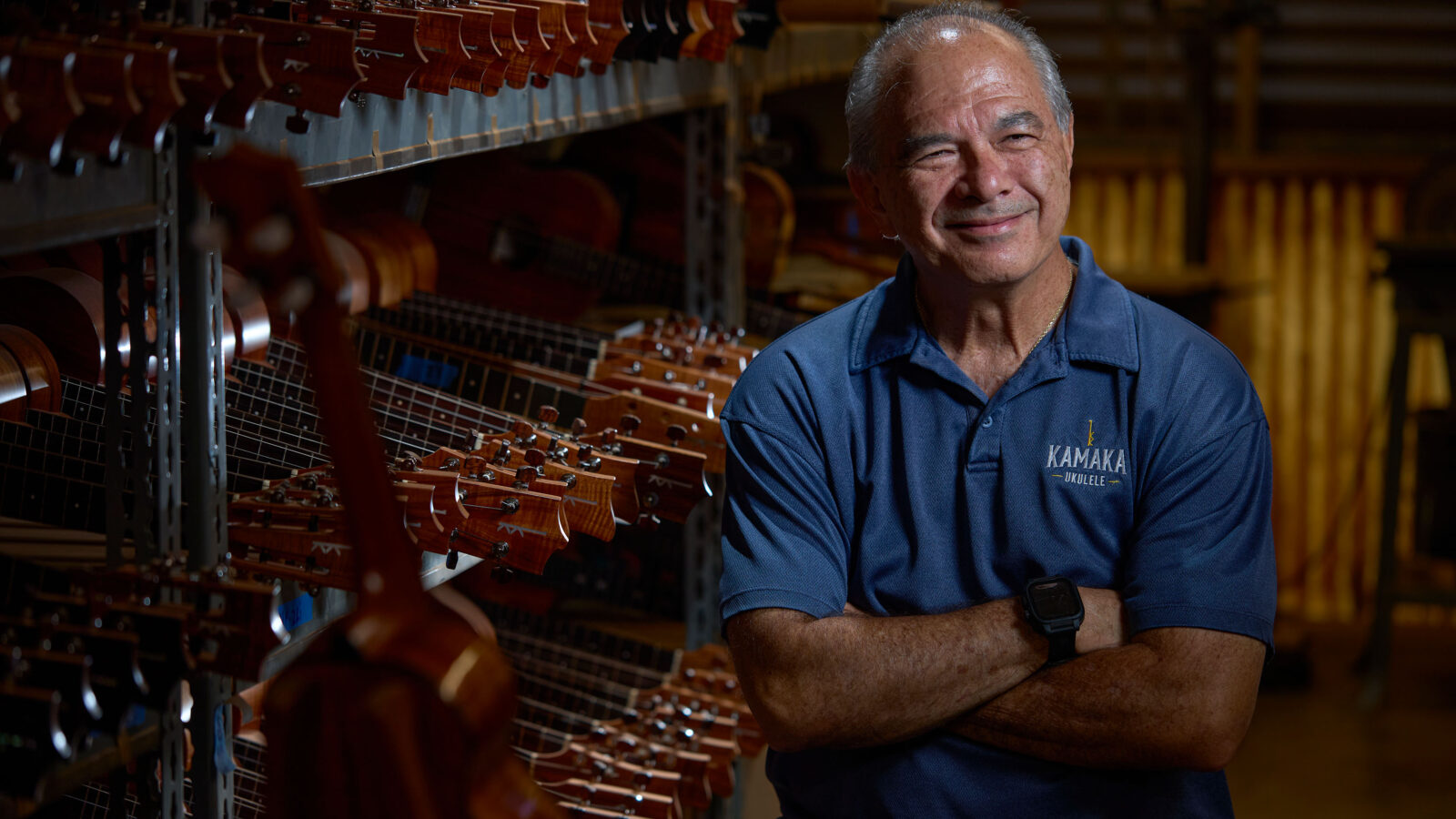

Every year, Kamaka Hawaii crafts nearly 1,500 ukuleles in its Honolulu factory that are sold locally in Hawaii and shipped across the world. To ensure every Kamaka ukulele meets the highest quality standard, President and Master Craftsman Chris Kamaka personally plays and tests every instrument before it leaves the factory.

Handcrafted Excellence

If anything needs to be fine-tuned, the ukulele is sent back to the factory floor before it is shipped or sold. This tradition has been passed down from Kamaka Hawaii’s beginnings and is still going strong more than a century later. Founder Sam Kamaka Sr. played every instrument before it was sold starting in 1916 and later his son, Sam Kamaka Jr. continued the practice, playing and listening to every ukulele with a keen ear, and mentoring his sons, Chris and Casey, to listen in the same way.

“First, I visually inspect the instrument for any issues with the sanding and finish, and make sure it’s cosmetically sound,” says Chris. “Then I tap the top of the ukulele to ensure it has a good tone. My dad always told us to listen for that nice bell tone or ring. Throughout the building process, we are constantly tapping and tuning the top before it is secured.”

Chris and Casey discuss crafting the world-famous Kamaka pineapple ukulele.

— chris kamaka

“His ears are amazing,” says Casey Kamaka about his brother Chris. “They can hear things that other people can’t hear.” An ideal quality indeed when making sure every Kamaka ukulele meets the highest quality standards. Chris is currently training his son, Christopher Jr., and another Kamaka craftsman on what to listen for when playing every ukulele before it leaves the shop.

“After visually inspecting the ukulele and playing the instrument to hear its tone, I adjust the action,” says Chris. “That means setting the strings at the correct height above the fingerboard. I test the ukulele’s intonation and playability so when a customer plays the ukulele, it feels comfortable and they won’t want to put it down.”

For Chris, the commitment to quality is built into the fabric of the Kamaka family. “We don’t cut corners by speeding things up,” he says. “We take our time to make sure it’s done correctly. The time we put in is essential so we can make sure the instruments we’re making are as close to perfection as possible.”

Young Chris Kamaka

Every Detail Matters

This value was instilled in Chris at a young age when he helped out at Kamaka Hawaii as a boy. “My dad taught me patience, attention to detail, and how to treat our customers well.” At the age of 16, he worked for the family business after school and on the weekends doing various jobs like putting on keys, stringing the ukulele, and gluing embellishments. Together with his brother Casey, he eventually learned every step of the ukulele making process from their father, Sam Kamaka Jr.

“My dad hired hearing-impaired craftsmen over a span of 50 years, and he taught them what to feel for in their fingers as well as the vibrations of their bodies,” says Chris. “Many of us had the opportunity to work with them and learn what they were feeling for. They took so much pride in their jobs and building these instruments knowing they would never actually hear the music they created. We try to instill that with our current employees, to not only listen but to feel the life in the instrument as well.”

After graduating from St. Louis School, Chris worked for Kamaka Hawaii full-time while also attending the University of Hawaii at Mānoa where he earned a degree in business and art design. While attending college, he maintained his interest in music as a member of the Chamber Singers and Concert Choir. Chris was inspired to sing after listening to his father’s musical harmonies when he sang as a member of the Kamehameha Schools Glee Club. An accomplished musician himself, Chris has won three Na Hoku Hanohano awards for his music as a stand-up bass-playing member of the popular Hawaiian music groups Kealohi and Hookena, and was nominated three times for a Grammy award. “I think of my parents when I play songs my parents love. My dad would always sing ‘Maui Waltz’ to my mom.”

“The ukuleles we’re making today are even better than what we made before,” says Chris. “But when people bring their older Kamaka instruments into the shop for repairs, they still sound amazing, like a Kamaka ukulele should sound.”

To Chris, quality means the relentless pursuit of perfection. “It means using the best materials, the best koa wood, the best hardware, keys and strings. It means every detail matters. Every detail counts.”